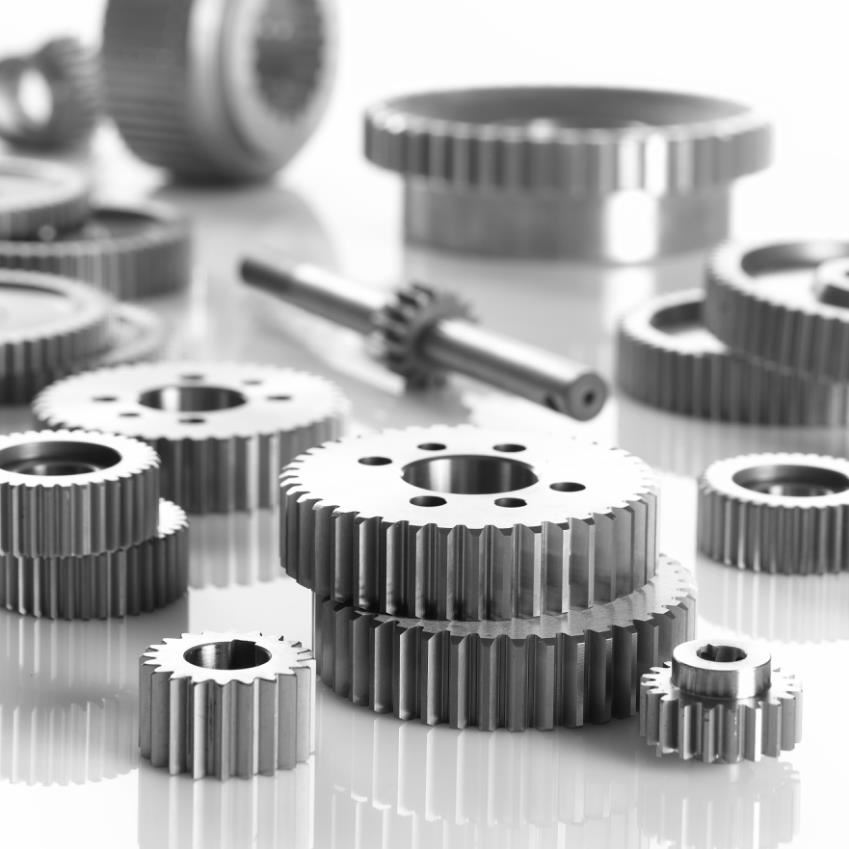

Spur gears

Spur gears, commonly referred to as spur gears, are used in multiple applications requiring the transmission of large torque by placing them on parallel shafts that rotate in opposite directions.

Main advantages of spur gear:

- High transmission efficiency

- Compact and very easy to install

- Constant gear ratio

- High reliability

Common applications:

- Cutting machines

- Marine engines

- Motors and gear pumps

- Rack and pinion mechanisms

- Handling equipment

External spur gears

- Module 0.5 to 10

- Maximum tooth diameter: 500 mm

- Maximum tooth length: 1000 mm

- Pressure angle: 20 °, 30 °, 45 ° and special

- Max quality: DIN 4 (rectified)

Internal spur gears

- Module 0.5 to 10

- Maximum tooth diameter: 500 mm

- Maximum tooth length: 200 mm

- Pressure angle: 20 °, 30 °, 45 ° and special

- Max quality: DIN 8 (cut)

Sprockets and pulleys

- Sprocket diameter according to drawing specifications

- Maximum tooth diameter: 500 mm

- Maximum tooth length: 200 mm

- Type of belt gears: synchrobelt, optibelt, etc.