Expertise

GRIMONPREZ GEARS & GEARBOXES companies are your partner for all your gears, transmissions and gearboxes projects.

We manufacture high quality gears, reducers and multipliers. And internally perform the following operations:

- Turning

- Milling

- Gear cutting

- Broaching

- Slotting

- Heat treatment

- Cylindrical grinding

- Gear grinding

With the GRIMONPREZ companies, you are guaranteed to have tailor-made support according to your projects.

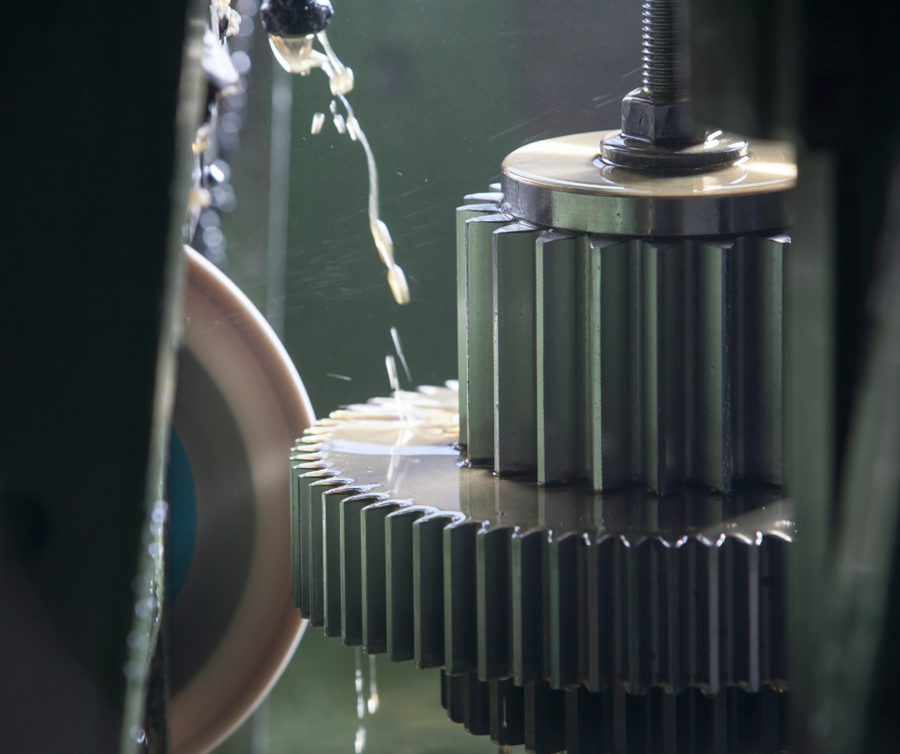

Gear hobbing

Gear hobbing is the most widely used process for manufacturing gears by removing material, regardless of size.

It is based on the basic principle of a wheel system (the gear) and an endless screw (the hob). During the cutting process, they turn in coordinated rotational movements.

Thanks to this technique, it is possible to manufacture:

- Spur and helical gears

- Module 0.5 to 14

- Maximum teeth diameter: 600 mm

- Maximum tooth length: 1000 mm

- Maximum quality: DIN 4 (rectified)

Gear shaping

Gear shaping has the advantage of significantly reducing processing time and thereby increasing productivity.

Thanks to this technique, it is possible to manufacture:

- Spur and helical gears

- Module 0.5 to 10

- Maximum tooth diameter: 500 mm

- Maximum tooth length: 200 mm

- Maximum quality: DIN 4 (rectified) / DIN 7 (cut)

Special processes

We offer several special processes:

- Deburring

- Grooving

- CNC broaching

- Automatic straightening

- CNC deep hole drilling

- Deburring is the removal of burrs from a forged or stamped part.

Grooving consists of digging grooves, notches in the part.

CNC Turning

Turning is another machining process which consists in obtaining cylindrical or conical parts using cutting tools on lathes, by removing chips.

Gears with a diameter of 50 to 500mm are machined in small and/or medium series on multifunction turning centers in place and instead of conventional or numerically controlled lathes (horizontal single spindle, horizontal multiple spindles, vertical single spindle).

CNC Milling

Milling refers to the removal of material in the form of chips. We offer you :

- Machining center with an additional 4th CNC axis

- 3, 4 and 5 axis machining

- Machining of long parts

- Drilling

- Tapping

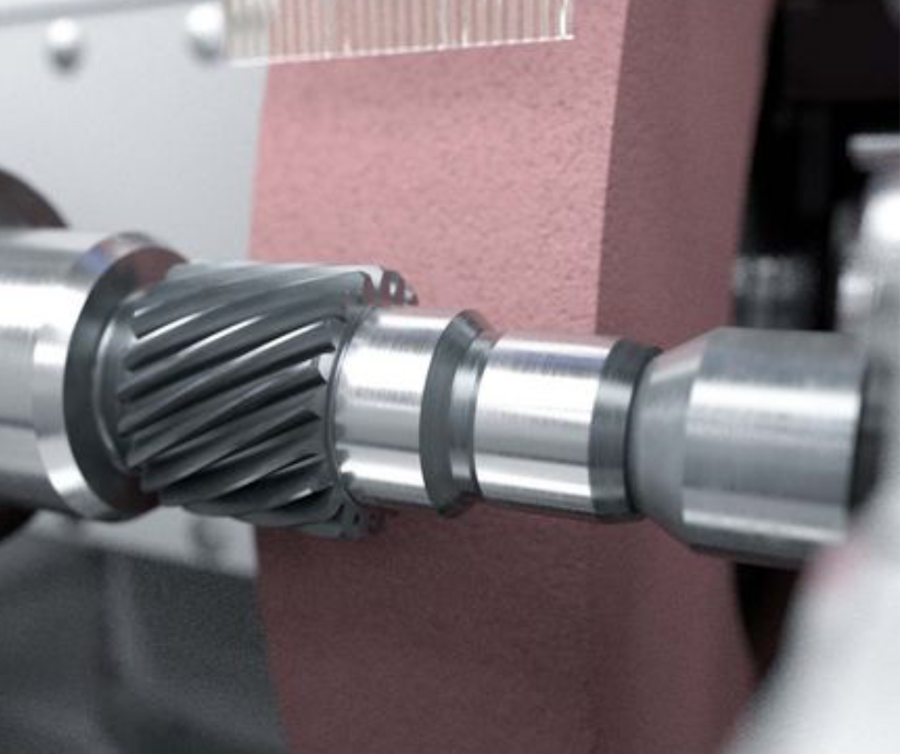

Cylindrical grinding

Cylindrical grinding consists of machining by abrasion. It makes it possible to obtain perfectly cylindrical surfaces. We grind teeth:

- Exterior and interior

- Diameter 50 to 500mm

- In ceramic grinding wheel or CBN

- In straight or oblique dive

Gear grinding

Gear grinding makes it possible to finalize a gear-type mechanical part with the greatest precision

We grind gear:

- Diameter 50 to 500 mm

- Vitrified grinding wheel

- Grinding in vitrified mother wheel

- CBN wheel grinding

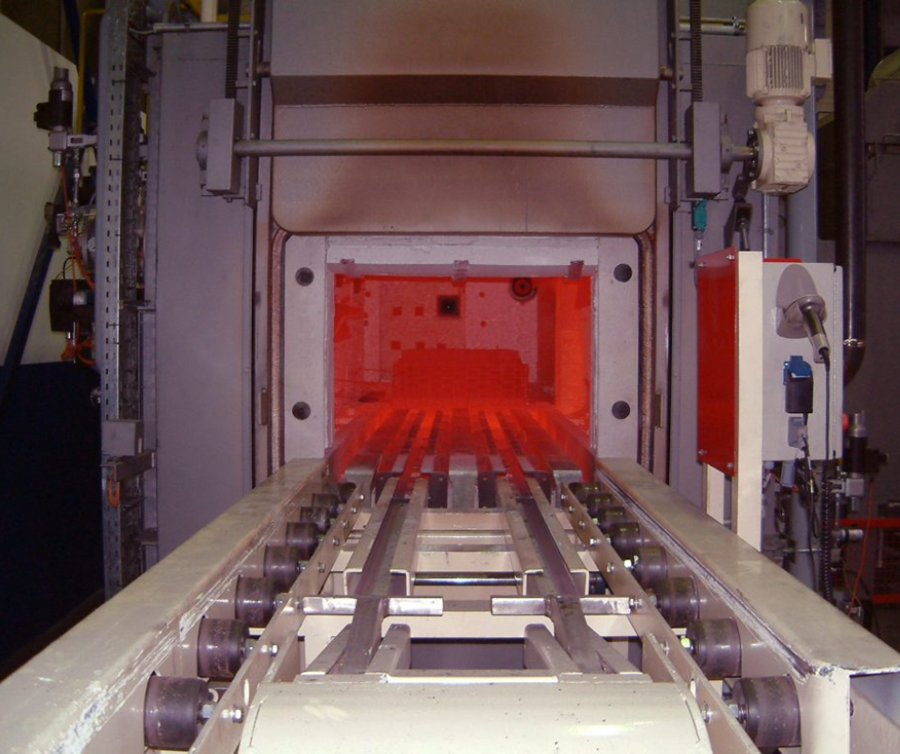

Heat treatment

Heat treatment consists of modifying the microstructure of materials such as metals and alloys, i.e. subjecting it to structural transformations through predetermined cycles of heating and cooling in order to improve their mechanical characteristics. : hardness, ductility, elastic limit, service life...

GRIMONPREZ TRANSMISSION GEARS offers the following heat treatment processes:

- Induction hardening

- Revenue

- Carburizing

- QPQ

- Phosphating

Forge

Thanks to a panel of European suppliers, we are able to offer you all types of high quality forges in order to meet all the needs of your projects.

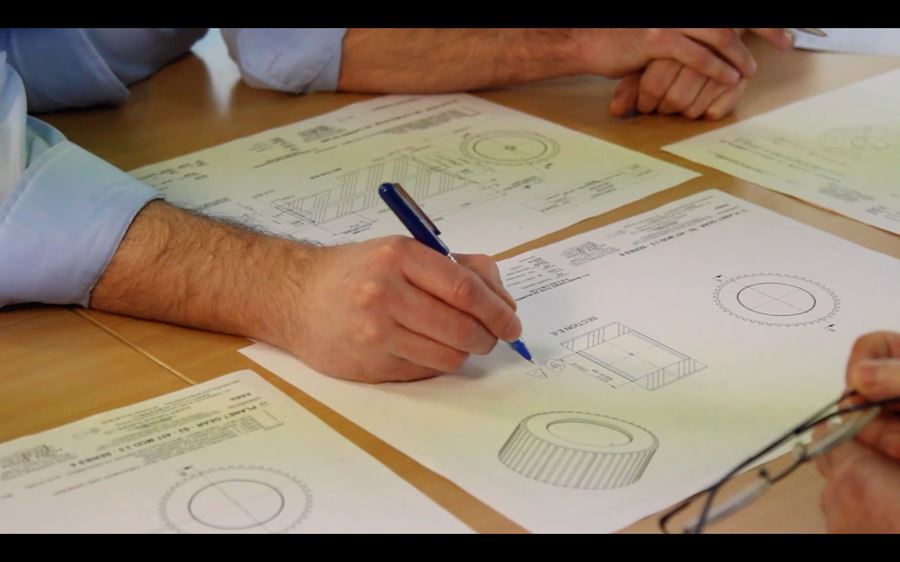

Design office

Thanks to our dedicated design office, you have at your disposal a project team specialized in transmissions. Our engineers support and advise you in all your industrialization projects.

Our design office has a KISSsoft® license, which is a modular structure calculation software for the dimensioning, optimization and verification of mechanical components according to international standards. This allows us to offer you cost optimization solutions.